Tesla CEO Musk predicts battery production by end of ‘16

STOREY COUNTY — Tesla CEO Elon Musk said Tuesday he is ramping up construction of the electric car maker’s Nevada gigafactory primarily because of anticipated growth in demand for the company’s moderately priced Model 3 car.

Musk, who answered questions from the media after a tour of the gigafactory under construction east of Reno, said Tesla expects to achieve sales of 500,000 of all of the company’s all-electric vehicles in 2018, two years ahead of schedule.

The Model 3 is expected to sell for about $35,000. More than 370,000 people have reserved Model 3s with the company.

As a result, the gigafactory will need to boost production of the lithium-ion batteries that will be assembled at the factory at the Tahoe-Reno Industrial Center. The company says making its own lithium-ion batteries at the scale the gigafactory will allow will reduce its battery costs by more than a third by 2018.

The $5 billion gigafactory is now expected to begin producing the batteries late this year, ahead of schedule. The assembled batteries will be shipped by rail to Tesla’s car manufacturing facility in Fremont, California.

“The gigafactory is the most exciting factory in the world,” Musk said. “You have to think of the factory as more important than the product itself.”

So far the building is 800,000 square feet, with 1.9 million-square-feet of manufacturing space on as many as four floors. The factory will be expanded in modular units as demand grows for the lithium-ion batteries that will be produced at the plant for its vehicles.

Musk and JB Straubel, chief technical officer of Tesla, spent more than an hour answering questions.

I AM here. #RJnow pic.twitter.com/MOCTfTU5lH

— sean whaley (@seanw801) July 26, 2016

A #Tesla in front of the Gigafactory. #RJnow pic.twitter.com/CKMyEAI90y

— sean whaley (@seanw801) July 26, 2016

Work on new phases of the factory is already underway both on the south end and north end of the nearly finished first phase of the factory. The current size is only about 14 percent of what is expected as construction continues over the next several years. Upon completion at 10 million square feet — roughly the size of 262 NFL football fields — it will be one of the largest buildings in the world.

The workforce, including construction workers, is comprised of about 70 percent Nevada residents, well above the 50 percent objective sought by the Nevada Legislature in September 2014 when it approved $1.3 billion in tax incentives over 20 years sought by Gov. Brian Sandoval to bring the company to Nevada.

With the planned production rate of 500,000 cars per year, Tesla alone will require today’s entire worldwide production of lithium ion batteries. The Tesla gigafactory was created to ensure an adequate supply of the batteries to support its projected demand.

The upstart electric car company, which has yet to make a full-year profit, wants to transition from a maker of luxury vehicles to a full-line maker of affordable cars, pickups and even semi-trucks. It also runs Tesla Powerwall, a solar energy storage business for homes and businesses.

The factory is expected to employ about 6,500 workers by 2020.

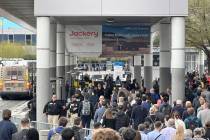

The factory was a hive of activity on the tour, both inside and outside. Outside, nearly 1,000 workers were laying the groundwork for the factory’s expansion, digging trenches and erecting steel supports. The interiors of the first phase of the facility are complete and equipment was being installed on the various floors.

Photographs and video were not allowed on much of the tour, and Tesla officials asked not to be identified by name for the story. Musk and Straubel spoke on the record.

The media tour came ahead of a grand opening for the company’s customers on Friday.

The Associated Press contributed to this report. Contact Sean Whaley at swhaley@reviewjournal.com or 775-461-3820. Find him on Twitter: @seanw801

RELATED

Tesla officials show off progress at Gigafactory in Northern Nevada

Tesla picks Nevada for Gigafactory