Safety worries about valley pipeline eased

The adage that time heals all wounds doesn't apply to gas pipelines.

So says Hal Bloch, who admits he's not a pipeline expert but nonetheless is a mechanical engineer and president of the Summerlin North Homeowners Association.

The association was concerned in 2009 when Kern River Gas Transmission Co. was preparing to boost the pressure inside its 36-inch-diameter steel pipeline that crosses residential areas of the Las Vegas Valley to deliver natural gas from Wyoming to California.

" 'The older, the weaker' is the adage when it comes to pipelines," Bloch said . "Adequate, supervised maintenance can mitigate that, but it's never going to get stronger."

Concerns of local residents whether the pipeline, which runs for 27 miles beneath Las Vegas neighborhoods, was safe resurfaced after recent gas pipeline explosions in California and Pennsylvania.

The Review-Journal looked at inspection reports, obtained through the Freedom of Information Act, and at a lawsuit filed when Kern River sought to increase pressure in the line.

Bottom line: The local line is newer, stronger, better designed than the ill-fated ones -- and it was inspected two years ago.

The 1,680-mile underground pipeline is a relatively young one as pipelines go. At 20 years old, it's made of carbon-steel, about a half-inch thick and coated with an epoxy substance to keep it from rusting in the caustic Mojave Desert soil.

The fact that pipelines don't get stronger with age has been proved over decades and as recently as September when a 54-year-old, 30-inch-diameter gas pipeline exploded in San Bruno, Calif., killing eight and destroying 38 homes. Because of bends and changes in diameter of the Pacific Gas & Electric pipeline, interior inspections using an in-line robotic tool known as a "pig," couldn't be conducted adequately.

California regulators held a public meeting on the catastrophe Thursday and decided to consider whether PG&E should face penalties for inadequate safety records prior to the pipeline explosion.

On Feb. 9, another gas pipeline exploded in Allentown, Pa., killing five and damaging more than 50 homes and businesses. The 12-inch, cast-iron main had no history of leaks in 83 years.

Kern River's interstate pipeline is much younger, is made of high-toughness steel and is better designed. It also will be routinely inspected every four years with high-tech equipment and so-called smart pigs, according to company officials.

"The pipe in the Las Vegas area was designed to hold a pressure of 2400" pounds per square inch, Kern River pipeline safety manager Von McAllister wrote in a response to questions from the Las Vegas Review-Journal. That section of the pipeline was last inspected with smart pig tools on Oct. 25, 2009, he said.

McAllister added that the pipeline meets or exceeds local, state and federal safety laws and the company "employs a stringent corrosion control program."

"The greatest threat to the integrity of Kern River's facilities is the damage that can be caused by a third party ... striking our pipeline with a backhoe or other large piece of machinery."

The stretch of the pipeline that crosses the Las Vegas Valley was installed in 1991, about the time Summerlin's villages were being built.

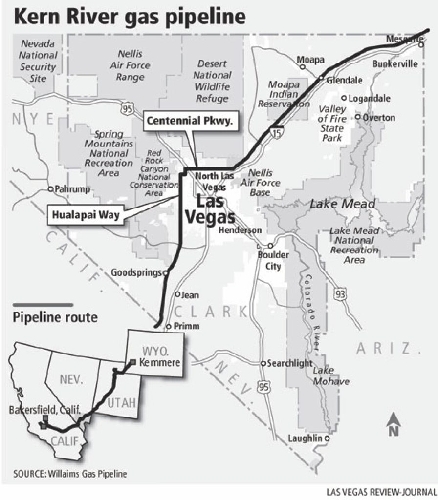

From Wyoming, where natural gas is tapped from the Rocky Mountains, the pipeline traverses Utah where it receives additional gas and enters Nevada near Mesquite, then parallels Interstate 15 to North Las Vegas.

From there it follows Centennial Parkway to Anasazi Drive, crosses Summerlin Parkway to Hualapai Way, across West Charleston Boulevard, then continues along Hualapai Way through the desert to Goodsprings and on to California where it connects with the Mojave Pipeline in San Bernardino County.

Though it doesn't run directly beneath homes in the Las Vegas Valley, attorneys for Summerlin's builder, The Howard Hughes Corp., argued in a 2009 lawsuit that Kern River Gas Transmission Co.'s request to regulators to increase the pipeline's pressure "has become increasingly important as Summerlin becomes more densely populated."

Buried from 7 feet to more than 17 feet beneath Hualapai Way, the pipeline weaves through residential areas, following an easement primarily along streets.

"Summerlin's many neighborhoods, parks, schools, golf courses, hospitals and businesses are now in close proximity to the pipeline," according to the lawsuit that sought to stop Kern River from increasing the pipeline's pressure from 1,200 pounds per square inch to 1,333 pounds per square inch.

A federal judge in Las Vegas denied a permanent injunction and the case was appealed to the Ninth Circuit Court of Appeals in San Francisco where a motion by the parties to dismiss it was granted in December.

"While we cannot comment on the court case that is under seal, we can say that our company filed comments with the Pipeline Hazardous Materials Safety Administration, which is charged with authorizing the safety aspects of Kern River's request for increased pressure. We filed the comments to help ensure that the most stringent safety measures and guidelines were scrupulously applied, and we also requested that federal authorities require Kern River to make the underlying information available to the public so that others could comment," said Tom Warden, a senior vice president for The Howard Hughes Corp.

While the litigation was proceeding, Kern River officials took steps to quell the concerns of federal safety officials who were reviewing the company's request to boost the pressure.

Documents obtained under the Freedom of Information Act show the company resolved safety issues for assessing corrosion and inspecting coatings and the electrochemical system used to protect the underground pipe from rusting. At least 14 other compliance inadequacies were fixed and some potential pipeline deficiencies were evaluated or repaired.

Chris Hoidal, Western Region director of the Department of Transportation's Pipeline and Hazardous Materials Safety Administration, had written a letter to the company's president, Michael Dunn, on Dec. 8, 2009, saying the administration "has specific concerns, and has determined that Kern River has not achieved compliance" with respect to several conditions.

"Kern River may not increase the pressure in its pipeline system beyond the existing (maximum allowed) until all of these Special Permit Conditions have been fully completed and implemented to (the administration's) satisfaction."

One attachment to the letter about an inspection of the pipeline's outer surface, noted "a severe anomaly" using one inspection tool while a different method found it to be "a moderate anomaly."

In either case, inspectors examining the location found that a 7-square-inch section of coating "was found to be missing where a railroad spike was in direct contact with the pipe."

Other "holidays" or places were coatings were missing were described in the documents.

But the shortcomings were addressed and the mainline transmission system was increased to 1,333 pounds per square inch on April 9, 2010, as authorized by the pipeline safety administration.

After reviewing inspection reports and the FOIA documents, Bloch said though he's still concerned about pipelines getting weaker with age, he feels more comfortable about Kern River's monitoring of the pipeline segment in Las Vegas.

"Where pipelines cross the path of the Kern River pipeline there can be corrosion problems and they've addressed that," he said.

He said he wonders why Kern River officials who attended a homeowners association board meeting in April 2009 didn't mention that they intended to inspect the pipeline in the following months.

"Why Kern River representatives never mentioned the 2009 run in our board meeting with them still sticks in my craw as it simply makes no sense for them to not get legitimate 'bonus points' from us on safety. But this omission is hardly something to go to war over."

The Associated Press contributed to this report.