Henderson company hopes to revolutionize process usually left to nuclear reactors

If you mentioned nuclear and Las Vegas in the same sentence 60 years ago, the conversation probably centered on the Nevada Test Site.

Today, you just might be talking modern medicine.

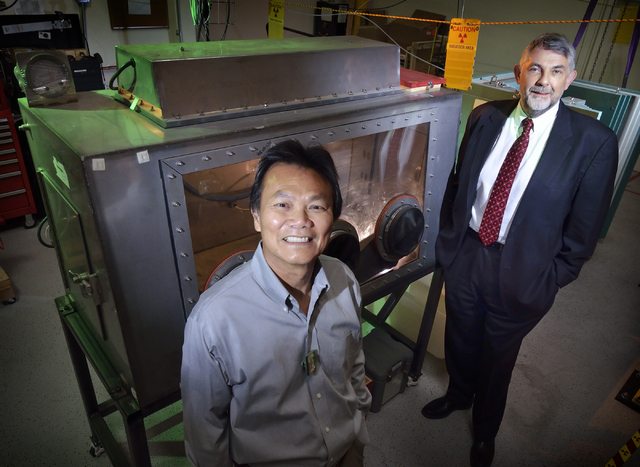

And if you’re Francis Tsang and Zane Wilson, you’re talking about a revolutionary medical business.

Tsang and Wilson are the principals behind Global Medical Isotope Systems, a Henderson company developing Tsang’s scientific breakthrough: creating a commercial production process for a chemical compound that, until now, only has been available from nuclear reactors.

That compound would be molybdenum-99.

Maybe it doesn’t sound familiar, but think back to high school chemistry. Molybdemun is element No. 42, symbol Mo on the periodic table.

A byproduct known as technetium-99m is used in medical imaging to highlight body systems.

Tsang’s device can make the vital material available right in Southern Nevada with a process a lot less gaudy than a power plant.

While the essential technological hurdles have been crossed, Tsang and Wilson must continually address issues of public safety, national security and nuclear nonproliferation. Their enterprise can address a potential problem facing the U.S. health care industry, which relies on scans of body parts to make clinical analyses for medical interventions.

“It’s considered a security issue as well as a national priority,” Wilson, chief executive officer of Global Medical Isotope Systems, said of the medical isotopes his company plans to produce.

Their goal is to address persistent interruptions in the supply of chemicals used in procedures to highlight organs or body tissues.

handled with care

But nothing is simple involving the branch of modern medicine inexorably linked to nuclear reactors.

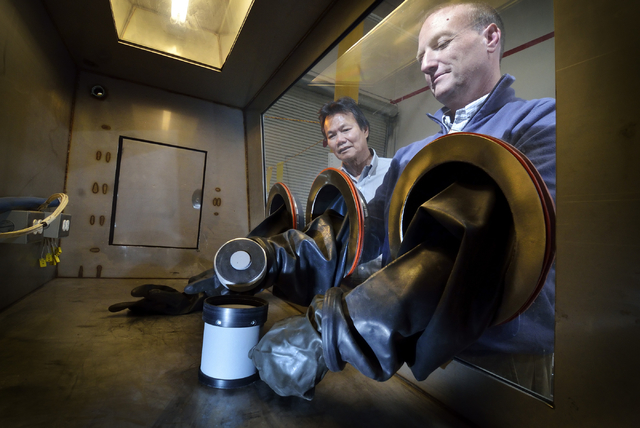

Ensuring none of the activity threatens public health, either from the release of radiation or the loss of any material that could be used as a weapon, is a challenge.

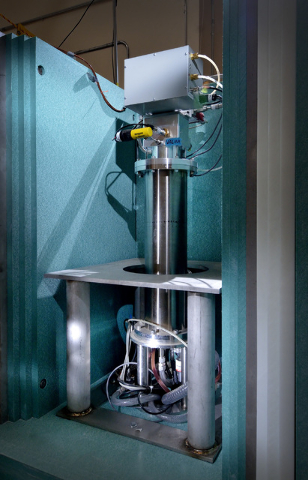

Tsang, the company’s chief technology officer, and Wilson, with support from experts in the University of Nevada, Las Vegas radiochemistry department, have developed a stand-alone system for making and capturing molybdenum-99.

Molybdenum does not occur naturally, and only minute amounts of technetium, molybdenum’s neighbor on the periodic table at atomic number 43, are found in nature. And neither substance is useful to medical professionals unless they are converted into an isotope, an unstable form of an element that gives off radiation to become stable.

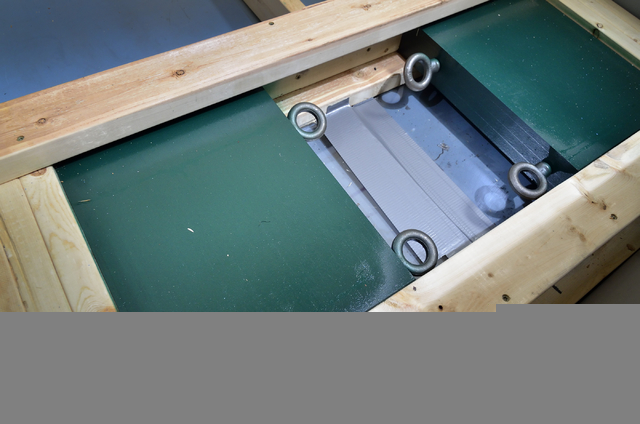

Tsang has invented a production and recovery process, coupled to a neutron generator that can produce the isotope molybdenum-99 from depleted uranium. Global Medical Isotope Systems recently signed a cooperative research and development agreement with National Security Technologies, known primarily as the management and operations contractor for the Nevada National Security Site (formerly the Nevada Test Site). Tsang and Wilson are benefiting from the expertise National Security Technologies officials have in system design, advanced modeling and radiochemistry.

“We have technical capabilities that can help this team,” said Chris Deeney, the chief technology officer for National Security Technologies. “We have a lot of experience in doing radiation detection, radiation monitoring, chemistry, modeling.”

Technetium-99m is the most common isotope in nuclear medicine, used in brain scans, cancer tumor imaging and renograms, which assess kidney blood supply and filtering action. As it decays, technetium-99m emits gamma rays that are detected by a gamma camera in single photon emission computed tomography, known as a SPECT scan. A SPECT scan produces images that show how organs work as opposed to X-rays that simply show what structures inside the body look like.

Molybdenum-99 is acquired through a complex supply chain starting with nuclear reactors outside the U.S. The isotope is shipped to processing facilities and distributed to generator manufacturing sites. The sequence can be disrupted by transportation issues such as customs and other government regulations, flight schedules and unpredictable weather.

The entire process is subject to very tight timelines because any manufacturing or transportation delays result in significant decay of the molybdenum-99, which has a half-life of about 66 hours. That means one half of the atoms of a given shipment disintegrate every three days.

Technetium-99m has a half-life of just six hours, which means the radioactive substance decays by 50 percent every six hours, making it impossible to store long term.

Half-life is the period during which a quantity of radioactive material decays to half its value. By comparison, uranium-235, the atom-splitting material used in the first U.S. nuclear bomb, has a half-life of nearly 704 million years, the time it takes before half of its radioactive punch decays to safer levels.

The short half life allows technetium-99m to be used in body-scanning procedures that collect data rapidly but keep total patient radiation exposure low.

Medical isotope shortages occur occasionally because of scheduled and unscheduled shutdowns of reactors, and from natural events. One shortage happened because of air traffic disruptions over the North Atlantic after an Icelandic volcano erupted.

The last facility in the United States that produced molybdenum-99 closed years ago as part of the U.S. nuclear nonproliferation initiative.

“The policy of the United States for a long time now has been to convince people that there’s no need to enrich uranium,” Deeney said.

Many of the players in both companies worked together for the U.S. Department of Energy at the security site, so the public-private partnership between the two entities was a natural fit.

“We’ve all been trained by the same people,” Wilson said.

team perfecting technology

By utilizing the expertise of Deeney and his team, Tsang and Wilson can focus their resources on the production process and perfecting the technology.

Safety is the priority whenever radioactive material is involved, but the beauty of Tsang’s production and recovery process rests in the substance essential to its operation: depleted uranium.

“Depleted uranium is not a multiplying medium,” Tsang said, referring to matter that can achieve fission, a nuclear chain reaction.

As former Department of Energy employees, officials from both companies know tight control over all aspects of the operation trump all other considerations.

“Special nuclear material is what Francis and Chris and I have worried about for most of our adult lives because you don’t want bad guys getting the ability to make bombs,” Wilson said.

Tsang’s invention has been verified by UNLV’s radiochemistry experts with spectroscopy, the use of spectrum analysis to study the interaction of matter and electromagnetic radiation.

“It’s an amazing process,” said professor David Hatchett, chairman of UNLV’s Department of Chemistry and Biochemistry.

Molybdenum-99 has been produced before outside a nuclear reactor, Hatchett said, but the yields were so low and the methods utilized were so inefficient that the processes were not commercially viable.

“It’s all been centered around a reactor, not a neutron generator,” Hatchett said.

Hatchett credited Tsang for his years of dedication in perfecting his device. The UNLV radiochemistry experts worked with Tsang to create the means of reclaiming the isotopes.

“We helped with that, but Francis is the driver. He had the drive to get that done,” he said. “He’s the one who came up with the idea.”

job creation foreseen

After Tsang and Wilson develop their molybdenum-99 production facility next year, they anticipate creating 50 jobs for technicians who could come from UNLV’s radiochemistry or nuclear medicine programs.

Having a production process for medical isotopes that’s not vulnerable to global supply chain problems also creates more stability for medical professionals who rely upon the material. Part of the reason Tsang began working on his invention stems from a friend of his who had cancer, and his treatment was delayed by a molybdenum-99 shortage in 2005.

Medical professionals use the lowest amount of radiation possible to perform the scans. A radioactive tracer is injected into a patient’s bloodstream, and the SPECT scan is performed after the targeted body system has absorbed the substance, which can take hours. The SPECT scan is a large circular device, and its camera detects the radioactive tracer. Images are generated by a computer that creates 3-D images of the targeted body tissues.

“The technetium allows you to see all this stuff. You bind it to different physiologic agents that are picked up by the body in different ways,” said Dr. David Steinberg, a radiologist and managing partner of Steinberg Diagnostic Medical Imaging. “You can bind the technetium to something called MDP and do bone scans. You can bind the technetium to something called Choletec and do gall bladder scans. You can bind the technetium to sulfer chloride and analyze gastric emptying.”

Most of the radioactive tracer passes from the body in urine within a few hours after the procedure, and because the half life of technetium is so short, the risk to patients is minimal.

The medications used in SPECT scans are processed in nuclear pharmacies. In Southern Nevada, Cardinal Health, PetNet Solutions and Advanced Isotopes of Nevada operate such facilities where molybdenum-99 is delivered, then placed in a generator where technetium-99m is captured.

A nuclear pharmacist combines the isotope with organic molecules that attach to form a tracer.

As soon as the technetium-99m is collected, the half-life deadline considerations begin. The pharmacists gauge how much time will elapse before a procedure is scheduled, and dose calculations are made. Quality control tests also are performed to ensure the tracers are properly formulated.

After delivery to a health care facility, the tracers are administered by nuclear medicine technologists. Additional tests are performed before the procedures to ensure the injections are viable. The contrast is delivered in a lead box to prevent the escape of radiation though the risk of exposure is minimal. If a procedure is delayed to the point where the tracer had lost its potency, the doctor would know after the tests were administered.

“The heart would just not light up,” said Dr. Keshav Chander, a cardiologist with Smart Heart Care of Las Vegas. “Our cameras are catching that radioactivity, and if the dosage was too low, the image would not be of sufficient quality to help with a diagnosis.”

The ability to produce molybdenum-99 in Southern Nevada lets Tsang and Wilson eliminate logistical issues. What takes days to achieve today, could be reduced to hours. Their operation could be a isotope depot, delivering molybdenum-99 to nuclear pharmacies, or they could take the process a step further and collect technetium-99m itself.

Eventually they hope to replicate the technology to allow his process to be used anywhere medical scans are being performed. Their partnership with the Nevada National Security Site contractor is designed to accelerate that process.

For Global Medical Isotope Systems, National Security Technologies provides a wealth of technological expertise that Tsang and Wilson don’t have to acquire on their own. For National Security Technologies, the new enterprise broadens the perspective of the people who have 65 years of experience maintaining security at the Nevada Test Site.

“It’s a chance for us to exercise our skills,” Deeney said. “The government pays us to be ready for any technical challenge thrown at us. We can be really good at that when our people are agile and have been exposed to all sorts of challenges.”

The mutual benefits enjoyed by both companies adds to the excitement the men feel in developing an innovation with the potential to help medical professionals treat their patients.

“This is a real opportunity for Southern Nevada to be the nucleus for a very new high-tech industry, and we’re always open to supporting new technology,” Deeney said.

Contact Steven Moore at smoore@reviewjournal.com or 702-380-4563.