NLV company shows off inflatable space station module — PHOTOS

It’s almost inconceivable to consider launching a small package into space, inflating it like a balloon and living in it.

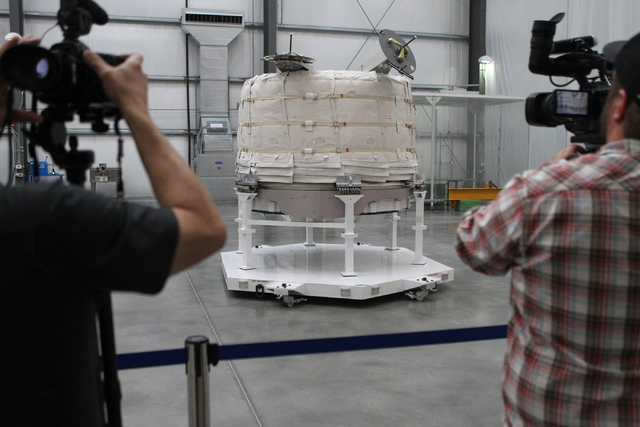

But that’s what North Las Vegas-based Bigelow Aerospace is working with NASA to do in the fall when the company’s first Bigelow Expandable Activity Module is placed into orbit and attached to the International Space Station.

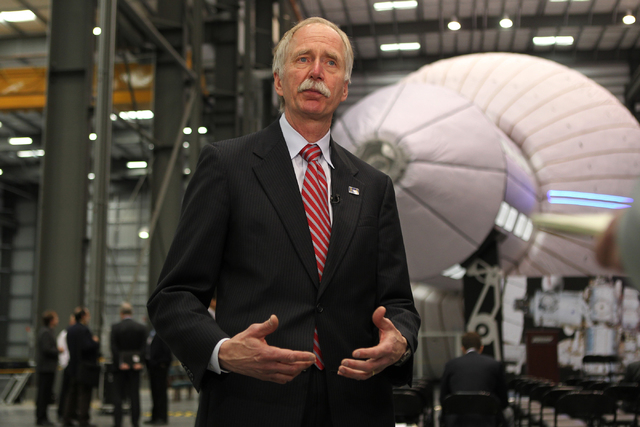

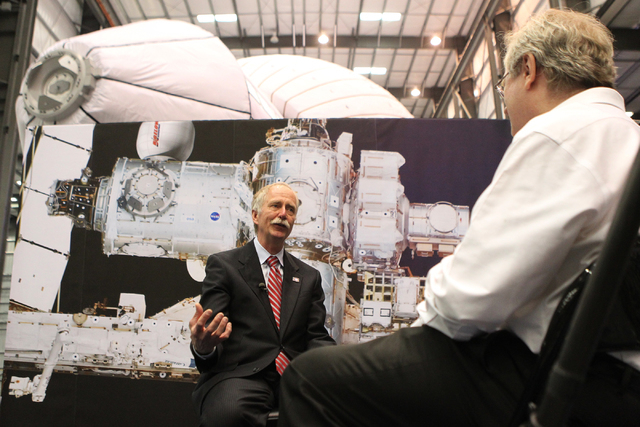

Before an international media contingent, company founder Robert Bigelow and William Gerstenmaier, associate administrator for NASA’s human exploration and operations, on Thursday fielded questions in advance of the BEAM module being shipped to the Kennedy Space Center on the Florida coast for an anticipated September launch.

The BEAM will be attached to the International Space Station — a process called “berthing” — and it will remain in place for two years while scientists and mission specialists conduct tests to determine its usability.

During its stay at the space station, scientists will test BEAM’s thermal properties and acoustics of the module and how it stands up to radiation and micrometeoroids.

NASA developed the concept of inflatable space environments and Bigelow built and tested models at its 350,000-square-foot facility on its 50-acre North Las Vegas campus.

“It’s definitely the spacecraft of the future,” said Bigelow, a Southern Nevada real estate and hotel developer with a fascination for space exploration.

The owner of the Budget Suites of America chain, Bigelow founded Bigelow Aerospace in 1999.

HABITATS FOR LONG-TERM STAYS

While Bigelow’s lodging interests have led many to speculate that he would develop orbiting hotels for space tourists, his work with NASA is to produce low-Earth-orbit environments for experiments and manufacturing, interplanetary living facilities for future missions to Mars and habitats for long-term stays on the moon.

Commercially, inflatable modules in orbit could house commercial research and small manufacturing facilities for pharmaceutical companies and engineers whose projects could be enhanced in a microgravity environment.

The BEAM is a scaled-down version of Bigelow’s planned B330 space habitat. It’s smaller than existing International Space Station modules, but the B330 is larger than them.

When developed, B330 modules will encompass 330 cubic meters of space — about 12,000 cubic feet — and would be a cylinder about 45 feet long with a 22-foot diameter.

Bigelow also is working on a module that is even larger than the B330.

While Bigelow and Gerstenmaier fielded questions from the media, the massive Olympus prototype module loomed behind them.

Gerstenmaier described the BEAM as more like a large tent than a balloon. Once it’s attached to the space station and inflated, it will provide additional room for station inhabitants.

“We’ll leave it up to those on the ISS (International Space Station) as to how much time they spend in it,” Gerstenmaier said.

He said “it may be a good place for crews to hang out in,” although it won’t have windows or an atmosphere revitalization system inside.

WEATHERING SPACE CONDITIONS

The tests that will be conducted will demonstrate how the module weathers space conditions. Because the space station will will have varying positions in relation to the sun, scientists will be able to monitor the effects of solar radiation on the module.

Bigelow and his team have had a long journey to Thursday’s BEAM sendoff.

Former NASA Deputy Administrator Lori Garver toured the Bigelow facility in February 2011 in advance of the space agency announcing that it would work with Bigelow, which began work on the BEAM project in late 2012.

Earlier, Bigelow had tested inflatable systems with the deployment of his smaller Genesis I system in July 2006 and Genesis II in June 2007 from Russian launch vehicles.

At the time, Elon Musk and his California-based SpaceX company was working on a space transport system and in 2010 launched its first orbital flight. By 2012, Musk — the same entrepreneur who is building the Tesla Motors battery gigafactory in Northern Nevada — launched a cargo delivery flight to the International Space Station.

In September, the BEAM will be the payload for the SpaceX CRS-8 mission, schedule to launch no earlier than Sept. 2. BEAM is the primary payload for the International Space Station resupply.

Once the craft reaches the space station, the station’s robotic arm will deploy the module and attach it to one of the station’s portals with a sophisticated computer program.

Once attached, it will only take about 4½ minutes to inflate the module and begin its two-year stay. BEAM has a self-inflating system or it can be expanded with pressure exerted from the main space station.

About 60 members of the Bigelow team were on hand for Thursday’s hourlong presentation.

“What has happened here in the past 2¼ years is a tremendous accomplishment for Bob and his team,” said Gerstenmaier, who Bigelow referred to as “the godfather of manned space these days.”

Contact reporter Richard N. Velotta at rvelotta@reviewjournal.com or 702-477-3893. Find him on Twitter: @RickVelotta