Las Vegas company creates 3-D car for SEMA

Local Motors in downtown Las Vegas has been teaching innovation to local students, while also leading the development of technologies that may someday disrupt the way consumers select and buy their automobiles.

The company was in the spotlight last month during the recent Specialty Equipment Market Association trade show at Las Vegas Convention Center. The local microfactory was involved in a demonstration in which a large-format three-dimensional printer fabricated a custom-car body and a team completed the car’s assembly. The project was finished during the trade show’s four days, in time to drive it during the annual SEMA Cruise and after-party.

“When SEMA approached Local Motors and asked us to ‘3-D-print’ a car at their annual conference, we accepted the challenge with great excitement,” Local Motors CEO and co-founder John Rogers Jr. said. “The hot-rod and aftermarket automotive community has always been on the cutting edge of vehicle innovation and we’re thrilled to display the future of carmaking to this group.”

Two-hundred automobile enthusiasts from 30 countries submitted designs for judging by their peers, in response to a six-week challenge launched by Local Motors last spring. The Strati, created by Michele Anoé from Italy, won the design competition. Then Local Motors’ automotive engineers and technicians built his concept car by using available technology from the Manufacturing Demonstration Facility at Oak Ridge National Laboratory.

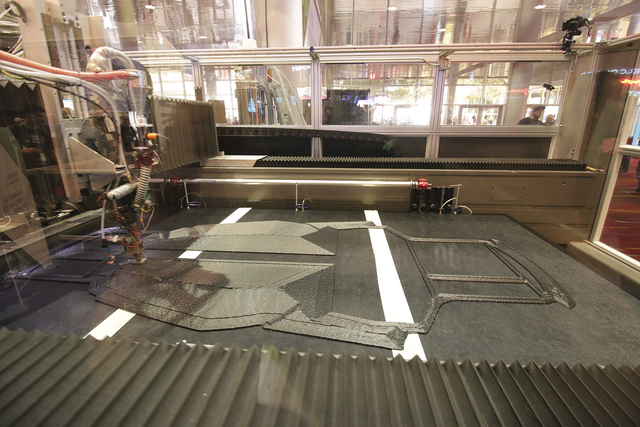

The first construction phase, fabricating the plastic and carbon fiber material components of the car body, started Nov. 4. Parts were made from scratch at the Las Vegas Convention Center. A Big Area Additive Manufacturing machine, manufactured by Cincinnati Inc., formed the components by melting and fusing rounded pellets of plastic into 212 layers of fine, stratified material over 44 hours.

The second construction phase used a five-axis CNC router to cut, grind, shape and refine the printed materials into finished components through subtractive manufacturing that took about eight hours.

The final phase began Nov. 6, when Local Motors’ team mated the electric-motor drivetrain, lights and peripheral components to the 3-D-printed car body. Assembly was finished by 3 p.m. Nov. 7.

The electric motor was rated at 17-brake horsepower and provided 42 pound-feet of torque. A 6.1 kilowatt-hour battery pack allowed the vehicle to travel about 62 miles between charging-station visits. Recharging time was about 3½ hours. The electric drivetrain had been donated by Renault and was adapted from the company’s Twizy electric car product line.

Local Motors has an online subscriber list of more than 30,000 international automotive designers, both amateur and professional, who contribute to vehicle design projects. (https://localmotors.com.)

To harness this worldwide community’s creativity, the company launched a new “ModMen Challenge” competition during the SEMA trade show, to see who could best modify an initial design for a car that was fabricated by a large-scale 3D printer. Twelve teams will compete to create the winning design that will be awarded in May. Local Motors will then fabricate the winning design and make it “highway-ready” in time for the next SEMA trade show at the Las Vegas Convention Center in November.

The company’s local Las Vegas microfactory on the corner of Sixth Street and Stewart Avenue has been helping local car builders realize their design dreams since the workspace was unveiled during SEMA 2013.

Gina O’Connell, the microfactory manager, along with Michelle Abbate and Scott Green, have been reaching out to local students and educational organizations, They aim to teach these new automotive design and fabrication technologies to Southern Nevadans.

O’Connell partnered with local nonprofit organizations and educational institutions, such as SYN Shop MakerSpace on Fourth Street, Girls in Tech Las Vegas, Findlay Middle School, Adelson Educational Campus, and Girl Scouts of the USA, to exhibit the company’s automotive designs and make them more accessible for students of all ages.

In 2015, Local Motors will partner with SYN Shop and the Henderson Library System on its “Generation STEAM” program, which will provide interactive workshops focused on science, technology, engineering, art and mathematics (http://hendersonlibraries.blogspot.com/2014/11/generation-steam-class-schedule.html)

The after-school workshops will provide hands-on opportunities for students to interact with some of the latest 3-D printing technologies at the Green Valley, Paseo Verde and Gibson libraries.

Stan Hanel has worked in the electronics industry for more than 30 years and is a longtime member of the Electric Auto Association and the Las Vegas Electric Vehicle Association. Hanel writes and edits for EAA’s “Current Events” and LVEVA’s “Watts Happening” newsletters. Contact him at stanhanel@aol.com.