Their prototype finally blew up on live TV Saturday afternoon, and the folks at Bigelow Aerospace couldn’t be happier about it.

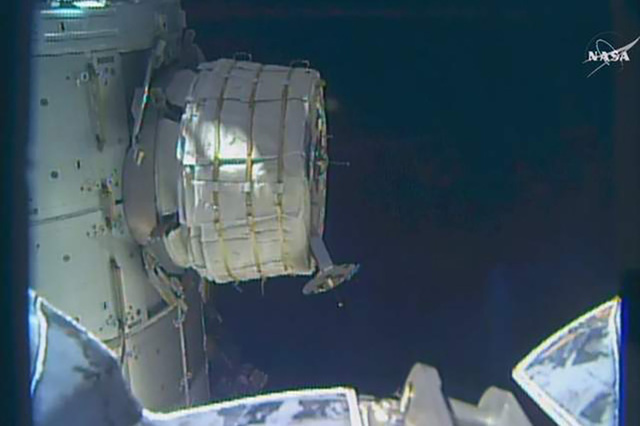

The North Las Vegas-built Bigelow Expandable Activity Module, or BEAM, was successfully filled with air and pressurized for the first time at about 1:44 p.m. local time by an astronaut on the International Space Station.

“For ourselves and our company, this is a huge day for us. I’m so proud of the whole team,” said Robert Bigelow, a Las Vegas native and hotel developer who founded the company in 1999. “It’s something I’ll remember for the rest of my life.”

The first attempt to fill the module early Thursday morning was called off after about three hours because it wasn’t expanding as expected. “You have to give NASA credit for being appropriately cautious because it’s never been done before,” Bigelow said.

The second try began at just after 6 a.m. local time Saturday, when NASA astronaut Jeff Williams began releasing small bursts of air from the space station into the module a few seconds at a time.

Popping sounds could be heard over the video link as the space habitat expanded.

After each burst, technicians at the Johnson Space Center in Houston would carefully check BEAM’s pressure and progress before calling for another dose of air from Williams.

That process repeated itself about two dozen times until the module finally reached full expansion at about 1:10 p.m. local time. Air tanks on board BEAM were then used to pressurize the habitat.

The operation meant a couple of hours of orbital overtime for Williams, who stayed up late and extended his scheduled work day to complete the job.

Saturday’s success marks the beginning of a two-year test to see how Bigelow’s design performs in the rigors of low Earth orbit.

BEAM is made from a variety of flexible materials layered together and reinforced like a steel-belted tire or a bulletproof vest to shield crew members inside from heat, radiation, tiny meteoroids and other “hyper-velocity” orbital junk.

In its expanded form, the barrel-shaped module is about the size of a small bedroom.

Once the module’s atmosphere is deemed safe, crew members wearing air masks and helmets will pop the hatch and venture inside for the first time, said Rajib Dasgupta, NASA’s project manager for BEAM, during a live video chat Tuesday on Facebook from the Johnson Space Center.

That is slated to happen in about a week, though no exact date has been set.

Crew members shouldn’t need protective equipment during subsequent visits, Dasgupta said. “The environment within BEAM is completely habitable.”

Just in case, though, the hatch leading into BEAM will remain closed for “safety reasons” except when crew members go inside to run tests and collect radiation monitoring equipment six or seven times over the next year, Dasgupta said.

The compressed module was carried into orbit by an unmanned SpaceX rocket on April 8 and captured by the space station on April 10.

Six days later, a robotic arm was used to unload BEAM from the trunk of SpaceX’s Dragon spacecraft and attach it to the station.

NASA picked Bigelow Aerospace to build and test inflatable space environments at its 350,000-square-foot facility near Martin Luther King Boulevard and Cheyenne Avenue in 2011.

Bigelow said that he initially was against taking on development of the BEAM, believing it would be a distraction to the development of the much larger B330 module.

“However, after giving it a lot of thought, I decided there were more positives than negatives. We learned a lot and enjoyed working with NASA for almost two years” on BEAM’s development, he said.

NASA and Bigelow believe the technology could lead to the development of orbiting labs, factories and flexible habitats on the moon and eventually Mars, because expandable modules are lighter and take up less cargo space on launch vehicles than traditional metal habitats.

The aerospace company is already developing two, much larger inflatable modules: the aforementioned B330, which is 20 times the size of the BEAM and equipped with its own life support system, and the Olympus, which is more than twice the size of the entire International Space Station.

Bigelow has said the first B330 could be ready to put into orbit by 2020.

Review-Journal writer Marian Green contributed to this report.

Contact Henry Brean at hbrean@reviewjournal.com or 702-383-0350. Find @RefriedBrean on Twitter.

RELATED

North Las Vegas company's space habitat rockets into orbit

North Las Vegas-based Bigelow Aerospace lands $17.8 million NASA contract