Effort encourages residents to warm up to recycling refrigerators

When many people get a new refrigerator, the old one becomes a spare, often underused and in an out-of-the-way spot.

Those old units, particularly the ones made before 1995, are less efficient and full of banned Freon. NV Energy is hoping to make old refrigerators a thing of the past and save customers money while giving them $50 for the company to destroy the old unit.

“Those old refrigerators use up to four times what more energy-efficient refrigerators use,” said NV Energy project leader Douglas Eddie. “Typically, they’re sitting in a 120-degree garage, and they’re working hard to keep three items cool.”

NV Energy estimates that customers can save up to $140 a year on utility bills by eliminating an old refrigerator.

The Montreal Protocol is an international treaty designed to protect the ozone layer by phasing out substances that are responsible for ozone depletion. A 1995 revision of it led to changes in the type of Freon used in refrigerators. NV Energy has contracted North Las Vegas company Jaco Environmental to break old refrigerators down into components and recycle them.

“We try to make the whole thing as convenient to our customers as possible,” Eddie said. “We’ll schedule a time that’s convenient for them and come out to their house to pick it up.”

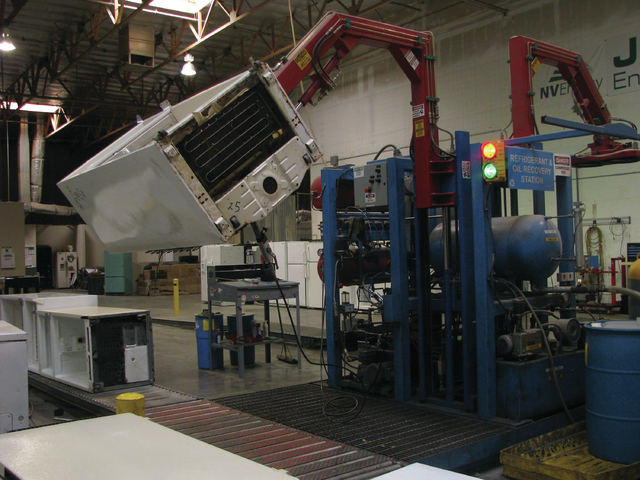

The recycling begins at the pick-up point, where a Jaco Environmental employee notes information about the refrigerator and assigns it a tracking number on a hand-held computer. When it arrives at the company’s facility, 2629 E. Craig Road, it is scanned and sorted, then the door, the plastic drawers, metal shelves and any other loose metal can be removed and recycled. It is then attached by suction to a two-sided machine that lifts the refrigerator and drains its oil and Freon. The machine then separates the two fluids.

The Freon could be recovered and sold at that point, but NV Energy and Jaco Environmental said they are committed to removing the ozone-damaging material from the market, so it is burned to provide power while rendering it inert.

From there, a worker cuts the unit into several large pieces with a reciprocating saw. The pieces are moved to another station, where the metal is stripped from the insulation.

“Pre-’95, all polyurethane foam was blown in using R12 Freon as a blowing agent,” said Mason Joseph, facility manager and director of operations. “The foam acts like a sponge and has Freon in it.”

The workers are careful not to crush the foam because it would release the Freon into the atmosphere. Another machine recaptures the Freon and grinds the foam into a powder, which is then made into pellets.

“Those pellets go into absorbent blankets that are used for oil spills,” Joseph said. “The blanket will still float even full of oil. It can be wrung out and reused a few times.”

The staff works fast and efficiently, and the unit rarely spends more than a few minutes at each station, Joseph said.

“It’s a good crew; they’re hard workers.” Joseph said. “We can easily process about 120 refrigerators in a day.”

To schedule a refrigerator pick-up, call 877-289-8260.

Contact East Valley View reporter F. Andrew Taylor at ataylor@viewnews.com or 702-380-4532.